Big Dipper Gantry Bearing

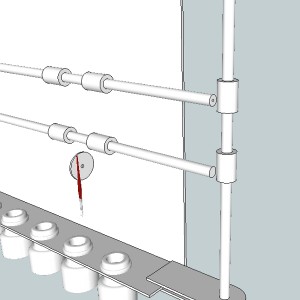

The Little Dipper (a 8.5×11″ format painting robot) is now ready for software which will take some reflection and time. While I mull over it, I will work on the Big Dipper hardware. I’m excited about the Big Dipper since it will have the larger format (24×24″) plus it is planned to be a very fast working robot.

I have the concept figured out and the parts so it’s just a matter of putting it together by filling in some of the blanks in my concept.

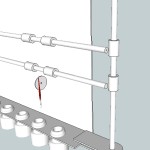

One thing that’s on my mind is the bearing blocks to connect the gantry “X-rails” to the vertical “Y-rails”.

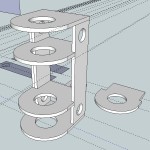

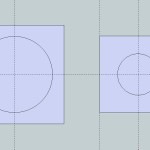

I wanted to come up with a bearing block that could be made with a laser. I had this hare-brained idea that I could make a series of plates with holes that matched the vertical bearings. They would stack together and a stepped hole would form on the edge of the stack to mate with the horizontal shaft. I went to draw that up to try it and it dawned on my that I could use inserts instead of having the stepped hole. It would have been nice except when I realized I was supporting two bearings on the Y-rail, the design came down to a box.

How boring. But I’m happy to have a basic bearing block come forward. I know this is profoundly boring but this is a great step for me since that bearing block was bothering me a bit.

I’ll finalize the bearing block after I figure out the Y-rails mounts, motor mounts, belts and pulleys.

One of the bearing blocks needs a motor mount and the other needs a pulley.