CNC Cart

I need a cart for the CNC613 project.

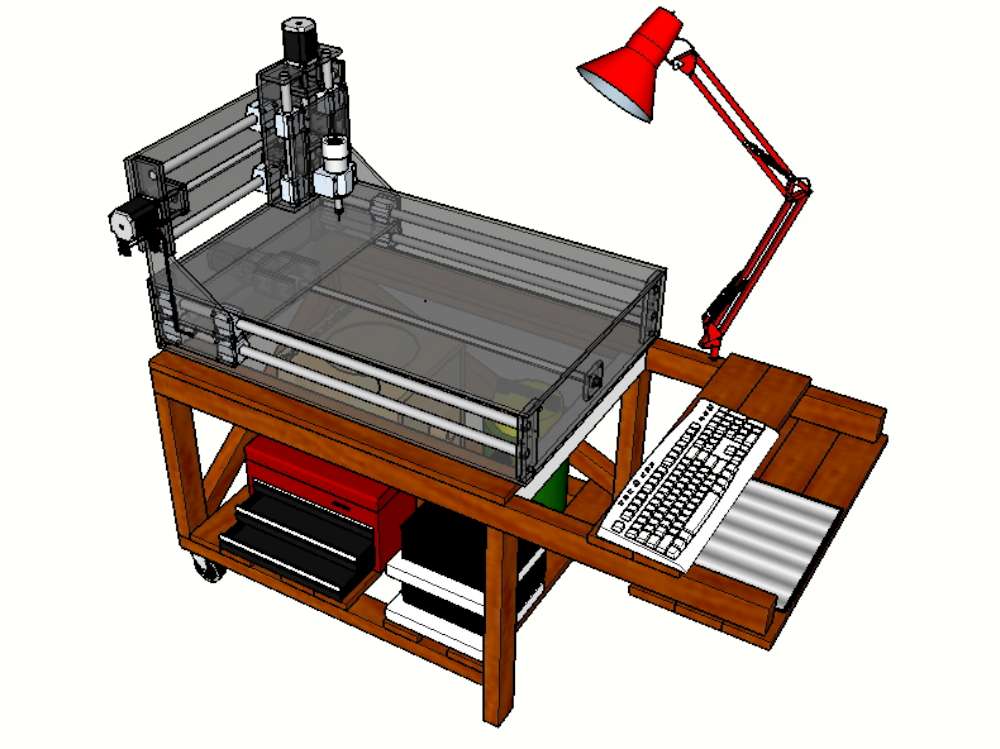

Here’s a concept I drew up that uses 24′ of 2×4 and 30′ of 1×4. I was thinking I’d use drywall screws and glue.

The lower tray has room for the vacuum box with dust extractor in the back. The front has a toolbox and the CNC controller boxes.

The computer tray has a place to lay the monitor flat and a keyboard.

I’ll probably add power bars. One for the vacuum, one for the lamp and computer and one for the cnc controller. So there’ll be three switches you can reach without bending over.

The computer and controller will be on epp foam to reduce vibration when the machine is being rolled around.

The gap between the machine and the keyboard is for clamping.

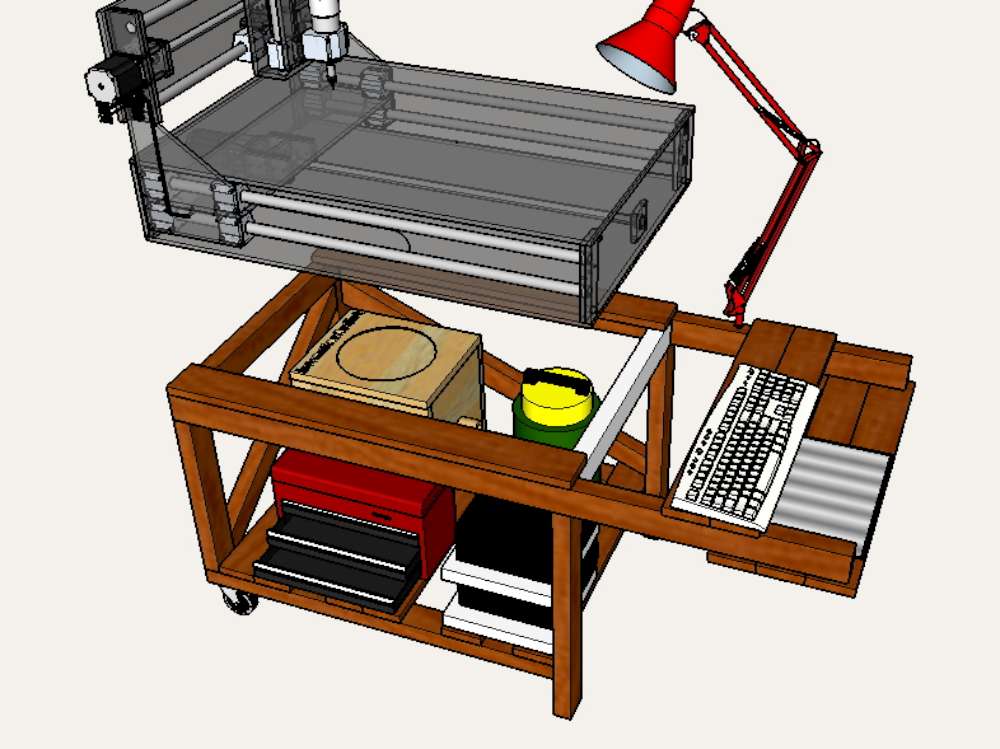

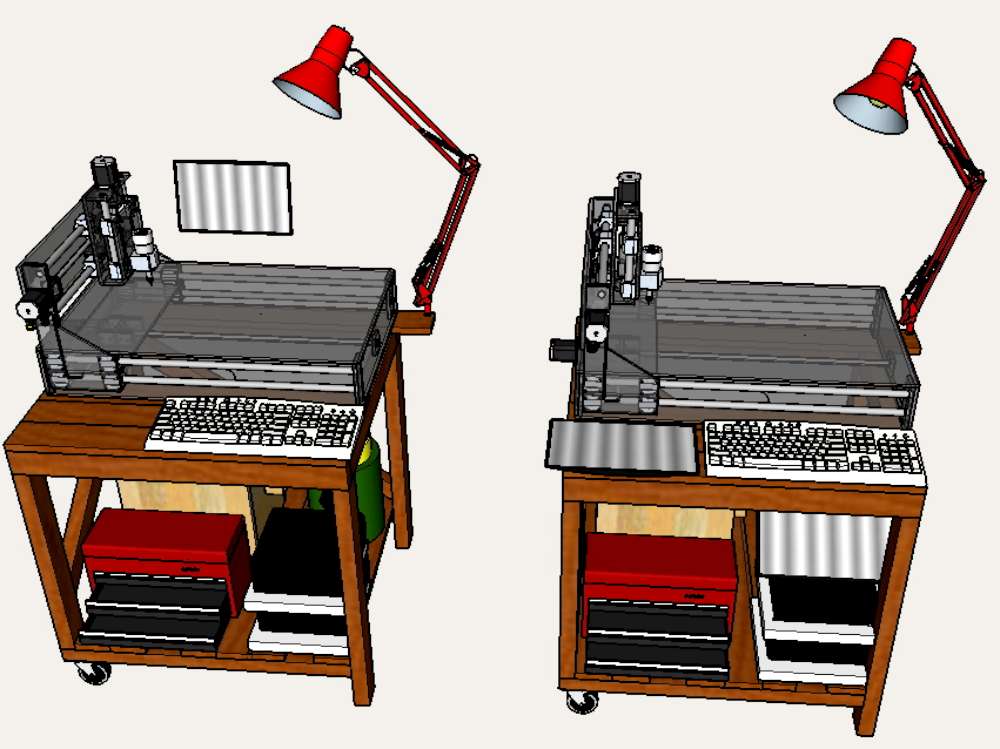

After getting some feedback a few changes were made.

The keyboard was moved to the side. I also left out the lamp fixture in favor of running an extension cord and extra wires through the drag chains and mounting lights on the gantry.

We managed to get it framed up at the Sunday Arduino meetup group (Hack613). I didn’t glue the lower shelf to make it configurable and it’d be easier to reuse that wood. Also I left the top shelving off since that can be added in a few minutes when we add the CNC machine. The cross braces will also be added at the time we add the load.

Bill of materials:

- 1×4 and 1×3″ wood

- drywall screws

- wheels

- some small powerbars to screw down

Tooling:

- table saw (in space)

- couple of drills. One for drilling and one for driving the screws. (I have these but there’s probably something in the space)

- belt sander (in space)

Sunset April 2016

With the new Make613 space there the cart isn’t needed so was dismantled. What to make out of the wood?

Not a bad design for a cart. I’d recommend a flip up cover for the keyboard as I’ve got mine two feet from my machine and it’s always full of acrylic chips which jam the keys. Also, locate one or more E-Stop buttons around the cart. The motor driver boxes would be happier with a bit of an enclosure, allowing air to come in from below so they don’t ingest a lot of swarf. Your sketch shows swivel casters on one side. With a tip up and roll setup, I’d opt for solid casters instead or it’ll be wobbly moving it around. The more you can enclose things, the less area there is for dust, chips and other junk to land on.

For my CNC table, I actually made what amounts to a large kitchen island out of IKEA kitchen cabinets. The outside, which goes up against the garage door, has 12″ cabinets for vertical storage of 24″ sheets of acrylic and other large pieces. On the inside. sets of drawers for tools, a large double door cabinet in the center for the dust collector, and a single door cabinet with shelving on the side for the computer and motor driver box. The top is 3/4″ plywood with 3/4″ MDF on top, and an edge cut from a 2×2 and stained black. It’s just high enough to keep tools from rolling off.

Thanks for the note. Those were just the first castors that came forward in google sketchup 3D Warehouse. We went plan wheels.

Your keyboard suggestion is a good one too. The plan is to not permit any swarf to leave the table with a vacuum system and also some barriers.

We should have it running soon so all those little refinements will be coming forward.

I’d love to post pictures of yours if you have any…

Even with a dust collector head on mine, I still end up with acrylic shavings all over the place. They’re near impossible to keep 100% contained unless you literally seal the machine inside a box and only move material in and out through a set of sealed doors. Of course that will make cleaning up between jobs far harder. I just resigned myself to having a dirty shop. There’s still chips all over the floor from last week’s parts session.

Here’s a pic of my CNC table:

https://scontent.xx.fbcdn.net/hphotos-ash2/v/t1.0-9/1175341_511876492223395_175138349_n.jpg?oh=3fe41f11613da5243ed78c430040933f&oe=55E13BCD

And the usual coating of acrylic snow:

https://scontent.xx.fbcdn.net/hphotos-xfp1/v/t1.0-9/16016_705349696209406_7921129397030446539_n.jpg?oh=12bb3b16ec0e401cd613e528f2a4463c&oe=55A0E487

I can’t get the links to work…

I’ll try thru Google Drive. Set to public. Should work.

https://drive.google.com/open?id=0B49Nil8ju370a3ZPNDJsb3NieWs&authuser=0

https://drive.google.com/file/d/0B49Nil8ju370bjdwdVdBVU5hQW8/view?usp=sharing

Wow that’s a hallofa mess you have there. 🙂

The worst is MDF. Stuff. Literally. Goes. Everywhere. Seriously thinking about sealing the entire machine into a box… except it’s rather big for that.

Dust collector or not, I spend a ridiculous amount of time vacuuming.