CNC Drop Trays

Here’s a CNC technique I’d like to share. When making small parts, instead of using tabs you can use drop trays.

Tabs (right) are used when you have a collection of parts still attached to a “tree” or material from which they were cut. In CNC fab it means you cut the part out but you leave some material behind to keep the part in place. They’re very popular since if the part comes off during cutting it will likely become damaged or worse become involved with the endmill (cutter) and get thrown. Also after the pieces are cut out, they all stay together in one convenient sheet.

On the downside, they need to be removed from the “tree/sheet” by the end user. There may also be a mark where the tabs were.

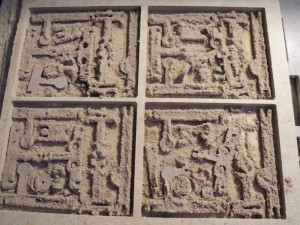

CNC Drop Trays (I may have made that up), are a space underneath what you are cutting. The piece can just fall downward once they are completely cut out. So the pieces are all in little trays after the cutting process. Once removed, you can vacuum the trays since the bulk of the dust will be there (another advantage).

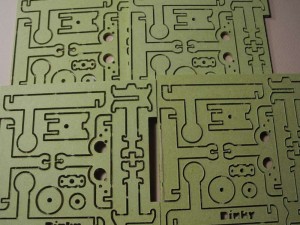

I’ve used this with the Dinky Motor prototyping and I must say… it works! The CNC system can be run with very light supervision and in the end all the parts are divided into little trays. I will adopt this.

[…] Cutting Trays for Dinky Motor […]