Got Dust? CNC Dust Control

I love my CNC machine but it generates loads of dust and swarf. So much vacuuming. Even when I changed the vacuum bag often it was still overloaded and spewing dust out the exhaust. Plus the vacuum exhaust blows dust up off the floor. I reached a point where I was letting the dust pile up and then removing it with a dust pan. I’d leave the room when the machine is running and only work around it after the dust was settled.

I love my CNC machine but it generates loads of dust and swarf. So much vacuuming. Even when I changed the vacuum bag often it was still overloaded and spewing dust out the exhaust. Plus the vacuum exhaust blows dust up off the floor. I reached a point where I was letting the dust pile up and then removing it with a dust pan. I’d leave the room when the machine is running and only work around it after the dust was settled.

I should mention that not all jobs are problematic. Anything with a 1/32″ endmill generates no dust to speak of. At 1/16″ we barely have dust but at 1/8″ dust is flying everywhere (I think dust volume increases with the square of the endmill size). Most of the jobs are 1/16th lately.

This whole thing has been getting on my nerves so I decided to solve it. With the techniques below I now have a nice clean work-space. What a relief.

Dust is a solvable problem. I just needed to spend some time on it. My solution is as follows.

- Dust skirt attached to spindle

- Cyclone dust collector

- Vacuum

- Vacuum Muffler

- Exhaust vent to outside

If anybody want’s any source files let me know and I’ll publish. They might be a proprietary towards my specific spindle an vacuum. But the dust extractor is pretty generic.

Boxes Vs. Dust Skirts

I’ve seen people build a cabinet around their machine. I figured I could make a box out of some thin strips of wood and then cover it with clear plastic (from a clear shower curtain). Perhaps a flap at the front and side so you can reach in even during a job to make adjustments. There could be a hoist to lift the box up to make it easy to work on the machine or load complex jobs. Or just use a cardboard box like they use at Ottawa University Makerspace.

Then I get thinking, what if I build a box just around the length of the gantry. It could ride back and forth on the gantry and could be a smaller box so it could just be lifted off and tossed aside. It could have a skirt that is near the work-piece so the dust would not escape.

Of course when I go to design it I realize I could just build a box around the truck on the gantry. It would be even smaller and even less work.

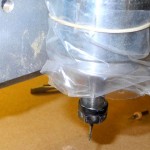

CNC Dust Skirt

I designed a simple box-skirt in Sketchup. My ER11 spindle has a 52mm diameter which is common. So if you have that you can use this design.

I cut the parts out (6600 rpm at 90ipm with an 1/8 inch 2-flute endmill). I “welded” the acrylic parts together using Methylene Chloride. In retrospect if I make another one I’ll just use hardboard. It’s nice to see the dust flow through but the Methylene Chloride is a nasty volatile poison and I’d rather not stock it unless I really need it.

That blue hose came from a home depot store. I think it’s the hose from a pool vacuum and I think I got it by the foot.

This actually works great but there are three issues.

- It’s an extra step to remove the shoe to change cutters. This doesn’t prove to be a very big problem. I’m suspecting the friction fit of the shoe is going to become an issue from wear.

- You have to watch out for the shoe hitting clamps and fixtures.

- My cheap vacuum is noisy. This is really serious. I can run it part time but it’s deafening.

CNC Miniskirt

For some jobs when the skirt/shoe gets in the way of the work-piece, clamps or fixtures, you can make a miniskirt. The cool thing about this is it is easy to change endmills as you can just pull it up.

For some jobs when the skirt/shoe gets in the way of the work-piece, clamps or fixtures, you can make a miniskirt. The cool thing about this is it is easy to change endmills as you can just pull it up.

The mill can’t throw chips and all the dust and debris just falls in place. There is no dust in the air. Then it’s a matter of vacuuming after the job is finished.

All it needs is some poly-bag and and elastic. I used 2mm poly (as slice off a 4″ wide bag). You can slide the bag up and down for each job depending how deep you’re cutting. Also make sure the miniskirt can’t contact the flutes. If it does I’m sure it will get sucked in and the endmill will likely break!

One could use this for a lot of types of work and not even bother with something more fancy. The only drawback is you have to vacuum at the end or do it manually during the job.

This is a lot better than it looks.

I got this ideas from Guy who was using a bigger skirt around the whole machine. It works pretty well as well.

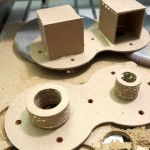

$1 Cyclone Dust Collector

Now that I’m running the vacuum frequently I’m concerned about the amount of time and money that will be spent changing vacuum bags.

Now that I’m running the vacuum frequently I’m concerned about the amount of time and money that will be spent changing vacuum bags.

The dust collectors are a little expensive and take a lot of space. I decided to simplify and try and make a bucket into a vortex of sorts.

I took a generic bucket and made two hose fittings out of hardboard. I added deflectors under each hose fitting to encourage the air to spin.

Works like a charm.

So this thing can intercept most of the dust that is en-route to the vacuum! All I need to do is empty the bucket! It’s so easy it just snaps off the lid.

This makes me very happy.

Note: I just figured out it’s called a cyclone dust extractor and not a “vortex dust extractor”. After googling it I found out my idea’s not unique. Here’s an instructable.

DIY Vacuum Bags

DIY Vacuum Bags

I decided to try to open the vacuum bags at the seem, empty them and reseal them. Perhaps a bag can be used three times or so. This will cut cost (and procurement/inventory of bags).

Further I think folding up a bag from raw material looks like a 5m job. I can reuse the little square mounting plate. Just rip off the old bag and glue the new bags to it.

So I will try and find some material to make the bags from. Perhaps fabric or there is a roll of special paper I can find. What material to use?

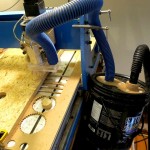

Vacuum Muffler

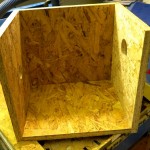

I put the vacuum into a box to reduce noise. The vacuum exhausts right into the box and then the box has a vent to let the air out. This dramatically reduces the noise so I won’t be afraid to keep the vacuum running.

The exhaust is pretty warm so I’m a little concerned it will overheat. The other thing is it’s a cheap vacuum. I’m not sure they’re really made for continuous operation anyway. I guess I will take it’s temperature and see where it stabilizes in and out of the box to see if there’s any difference.

Exhaust Venting

One issue I’ve had with vacuums is if they’re used a lot they start to leak some dust through the exhaust into the environment. Then your breathing it instead of just looking at it. I suppose if you get one with a filter and spend all your days and money changing or washing it or whatever that could help.

One issue I’ve had with vacuums is if they’re used a lot they start to leak some dust through the exhaust into the environment. Then your breathing it instead of just looking at it. I suppose if you get one with a filter and spend all your days and money changing or washing it or whatever that could help.

The vent on my muffler project above will have a hose mount and will be vented outside! Yippie! It’s gonna be like a dream!

Effectiveness to Date

I did a Dinky Motor run and a few other small jobs with just the foot connected to the vacuum. I must say things are a lot better.

This setup has given me great relief.

A Few Projects

Here are a few projects I’ve used my CNC for.

Big Oil Rooster (Rooster Art)

Cardboard Box Making

Tic-Tac-Toe (Small Tic-Tac-Toe)

Interference Rooster (Art)

Timeless Rooster (Art)

Microscope Stand (for electronics)

Hanging Chess (in progress)

Related

A point worth mentioning is that shop vacs are not necessarily made to run continuous (my $30 one I got on sale might not be especially).

Just a thought.

To avoid fire risk, I’m going to keep it light and always empty it every time. And stuff….

Comment I received in email:

You mean like this? https://www.youtube.com/watch?v=-Ct5R6_bj80

For the dust shoe, how about designing it in two parts that snap together using rare-earth magnets. The magnets hold the shoe in place when in use but you can pull it apart and out of the way when you need to change the bit.

DarcTry using a cyclone vacuum head over a regular bin/bucket… This extracts over 99% of the material before getting to the dust collector. All modern dust collection systems for woodworking incorporate a cyclone.

Magnets are a great idea, I’ll have a look at it!