Robots and Ink

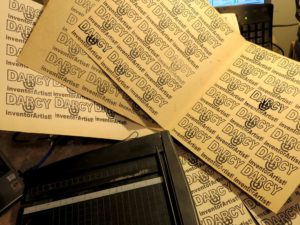

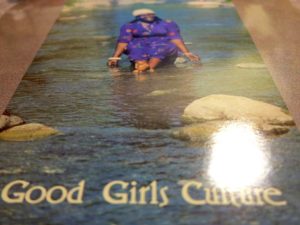

I’ve been making business cards out of record covers from LP vinyl (and many other things). They come out pretty nice (good, see below) but it’s a fair amount of work to stamp information on them (bad).

I’ve been making business cards out of record covers from LP vinyl (and many other things). They come out pretty nice (good, see below) but it’s a fair amount of work to stamp information on them (bad).

So I am now using a CNC machine to operate the stamp. For this I manually wrote the g-code (below) using NCPlot. I must say, NCPlot really speeds things up.

Here you can see the CNC acting as a robot to stamp my cards. So I’m able to make plenty of cards quickly.

The g-code came out like this:

(initialize machine to absolute, inches, XY plane)

G90

G20

G17(dip in ink)

G00 Z1.5000

G00 X14.5000 Y1.0000

G00 Z0.30000

G00 Z1.5000(stamp in place)

G00 X1.75000 Y1.0000

G00 Z0.00000

G00 Z1.5000(and so forth…)

I alternated back and forth between the ink and stamp sections. On the stamp sections I just in the coordinates of all the locations I wanted stamped. Worked like a charm.

I can see this standing in for a while to keep my business cards coming.

What to do to improve next?

Stamping Without Robot

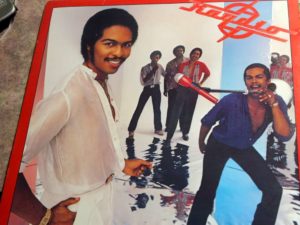

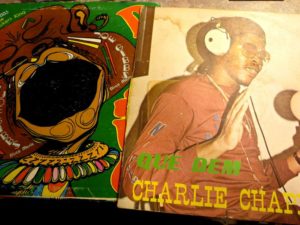

I have such a glut of record covers from the vinyl clock and vinyl jewelry projects. So I’ve been making these for a while.

I’m surprised stamped cards are not more popular among artists and such as this is pretty easy.

In one of the images you can see them along side my Spindle Adapter Cards and my Spirograph Cards.

Related

Published on: Jan 4, 2016 @ 16:44