DIY Electric Motor Assembly

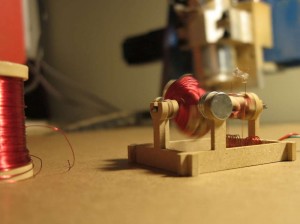

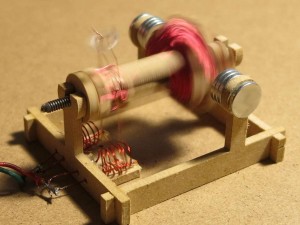

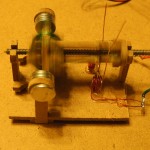

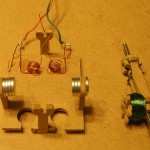

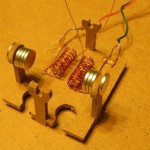

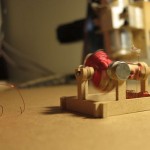

The electric motor project is coming along well. Here’s the latest revision based on 200 turns of 28 gauge wire per side. It’s probably the most powerful one so far. It even runs on the cheap ceramic magnets.

Here are the improvements.

- Larger lock nut for commutator. I also moved the holes that lock the wire in place to an easier location. This proves to be very easy to assemble.

- Longer commutator neck to separate the commutator from the coils. This leaves a lot more room for my fat fingers to wind the wire.

- Coil spring brushes. I changed the orientation of the coils.

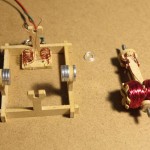

- Smaller rotor.

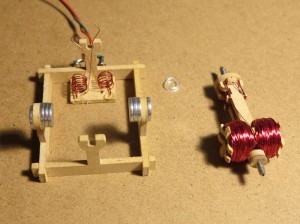

- I completely changed the platform. It’s now snap together and is self aligning. There are no more small parts. I made notches in a way that prevents them from going together wrong.

Here’s a brief video (of a slightly previous version) that shows how easy assembly is.

What’s Next?

-I’m looking at the brush construction. The pencil wound coil with plastic loop tensioner is working very well. I’ve got some construction ideas still floating in my head I will try.

-This motor actually runs off the cheap ceramic magnets. It runs weaker. The magnets I got were very small and I have some larger ones on order. I’m also going to consider using a coil instead of magnets since those rare earth magnets are fairly expensive. Perhaps I will make one with parallel coils.

-I previously made a gear box that connects to the motor. That’s pretty fun but I want to make a Zoetrope (video below) and perhaps a little car. Both the zoe and car will have a gear box and I think that will be way more entertaining and educational (aka fun).

-I think the method of connecting wires to the motor can be looked at. This will depend a bit on what kinds of power schools have in their learning environments. What I have might be okay but we’ll learn more about that when it comes to testing. Previous versions of the motor have been tested with a single AA cell and I’ve been doing most testing with a four pack. So the power requirements are pretty manageable.