Electric Motor Gearbox

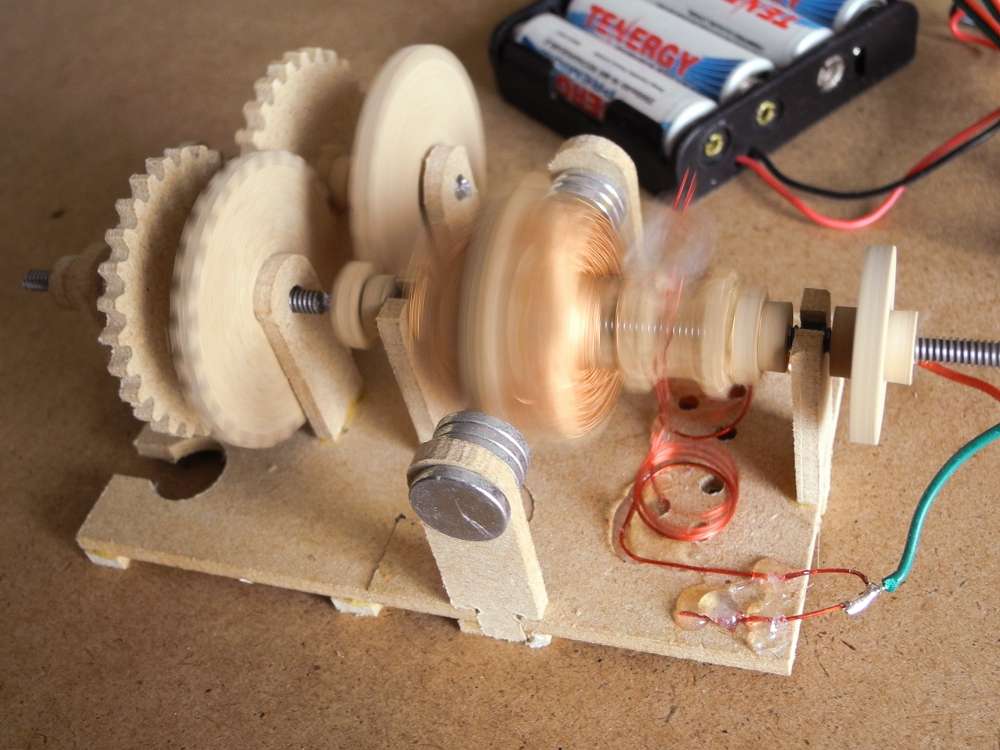

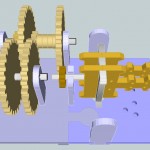

Here’s another version of the Simple Electric Motor project. I added a 4 stage gearbox to make it more fun and interesting. Each stage has a 4:1 gear ratio.

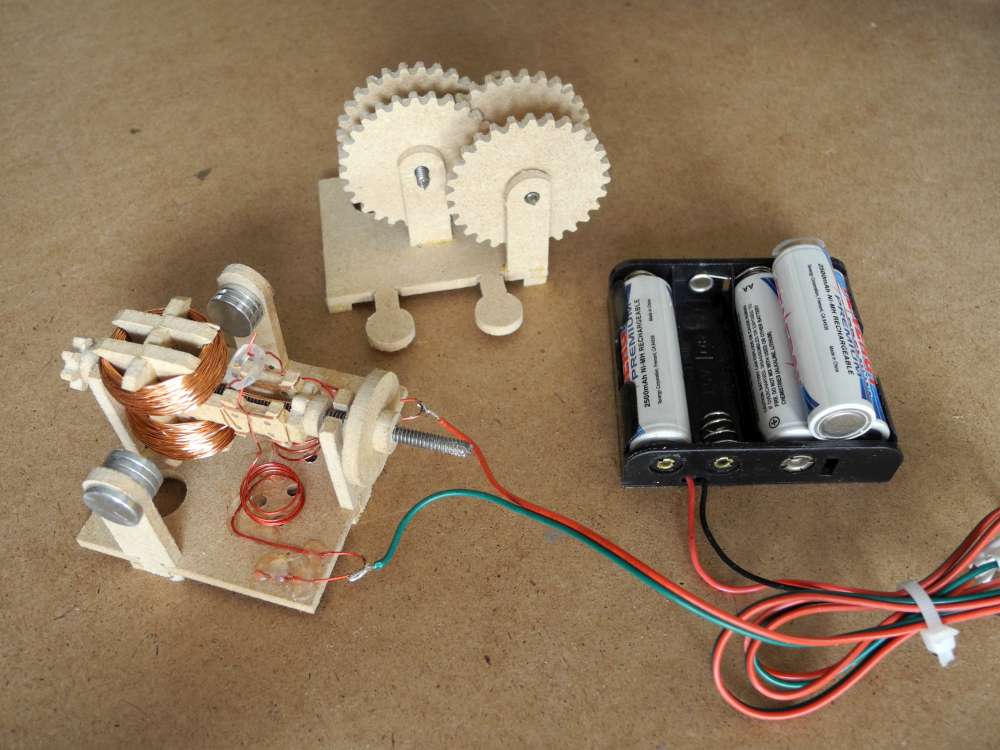

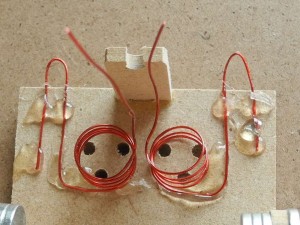

Here are the improvements on the motor side.

Here are the improvements on the motor side.

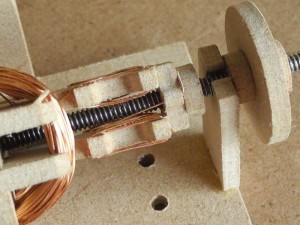

-The commutator lock-nut (circle) also locks the wire’s to the armature. It also locks the commutator to the motor shaft.

-A flywheel with two small circles to lock it in place.

-Puzzle connectors on base so it can connect to other projects such as the gear box.

-I tightened the fit of the armature assembly by 1/256″.

-The holes for securing wire to armature and commutator were moved to new locations.

-I shortened the commutator moving it further from the armature coils for easier winding.

-The armature parts were made to self align better. I used 1/16″ overlap instead of 1/8″.

-I made better feet for the platform (that use less material and are easier to install.

-I’m trying a small plastic loop as the brush tensioner.

-The magnet holders were moved in so less magnets could be tried.

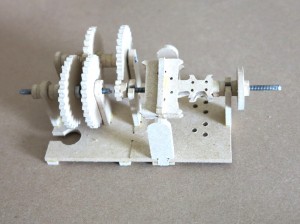

I made one on the CNC Mill. I used a 1/16th” end mill which worked very well. The gears (designed using Gear Generator WoodGears.ca) came out perfect.

The Good

-The gearbox runs very nicely.

-The armature literally snaps together. Very easy to glue it.

-Winding the armature is now very easy. You run the wire through a little hole in the commutator. Later the lock nut for the commutator also locks the wire in place.

-The puzzle connectors on the base work very well.

-It has 195 turns of 30 gauge wire per side and has plenty of power.

The Bad

-The gear box fits together well and runs smoothly. But it’s a bit tricky to put together. Much like a puzzle. I’ll have to put some thought into that.

Next

I am going to tighten the platform parts fit so it clicks together like the armature. I will also start to look at the shape of the platform and see if I can reduce the use of material (perhaps cutting some parts from the base).

I’m going to tighten up the armature to see if it can be cut away to accommodate more turns(or a tighter coil using less wire).

I’ve got some ceramic magnets on order. I want to try them and see if they work well enough.

I will start to look at a turn-table to snap onto the gear box.

I will have a look at the gear box construction to see what I can do about making it more obvious for assembly.