Dinky Motor Testing

Tonight was a Dinky Motors group build. The test group was just right so it was fun and we all learned a lot. Especially me. We had a lot of people interested in coming but many could not make it this evening so I will run another build session very soon. That worked out better as the next group will benefit from many kit improvements.

Tonight was a Dinky Motors group build. The test group was just right so it was fun and we all learned a lot. Especially me. We had a lot of people interested in coming but many could not make it this evening so I will run another build session very soon. That worked out better as the next group will benefit from many kit improvements.

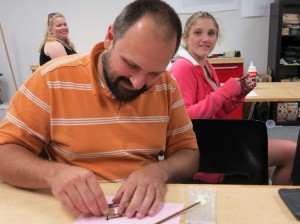

The group included Dave and family, Kyle and I. Kyle is a senior university student who is looking at the activity as a way of sharing science with kids at Let’s Talk Science.

This is a great activity for kids in general as it gives an awareness of electricity, magnetism, magnets and other miracles of our beautiful universe.

I noticed Dave’s kids already know about soldering, and electric circuits in general. Adults like it too since it jogs and challenges our existing knowledge plus it’s interesting to consider the possibilities of the design choices. Especially adults that have an interest in technical things.

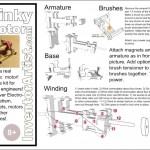

The instructions for the motor are still pretty immature plus with this style of social people are more interested in peer sharing than looking at diagrams and stuff. That’s what I expected and I felt it worked out perfectly because a lot of things that are wrong with my design came forward and there was lots of discussion. Also lots of ideas to consider for revisions.

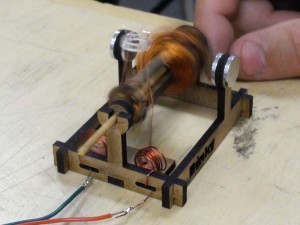

Dave tried the green 36 gauge wire. He didn’t have any more luck with it than me so I think I can dismiss it as too fragile electrically and physically. He also tried some variations on the brushes which look promising.

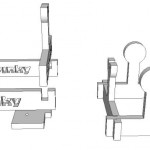

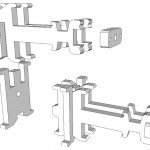

I’ve already made up a new design to try tomorrow. It has the following changes (many of which were in discussion with Dave).

- One of the shaft supports is closed so the motor will stay in better. I also reduced the size of the hole so there is less play.

- The motor was shortened slightly.

- I added a feature to the commutator shaft support so it will always be aligned properly.

- There are two new brush systems to test. A collection of holes and notches at the sides of the base and a collection of holes just below the shaft support (the brush platform was dropped for now). I’ll try them both tomorrow and report back.

- I will try a small AAA battery box. If it works out, it will be integrated into the motor base. I want to do a couple of revisions before actually putting it into the base since little changes like it’s width have a lot of impact on the motor.

From the discussions I think there is a great value of having a little car or truck that the motor powers. I think this will increase interest and motivation for makers and may even bring forward a competitive spirit for some. Now that Dave’s kids have built one, I think this could be what it would take to entice them to come back for the next group. Tomorrow while I’m testing out some brush configurations I’ll think of a car design that can integrate well with the motor.

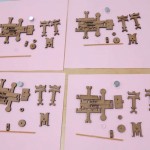

There is quite a bit of work in getting all the kits together but this session has increased my motivation. Here are a few shots from the preparation.