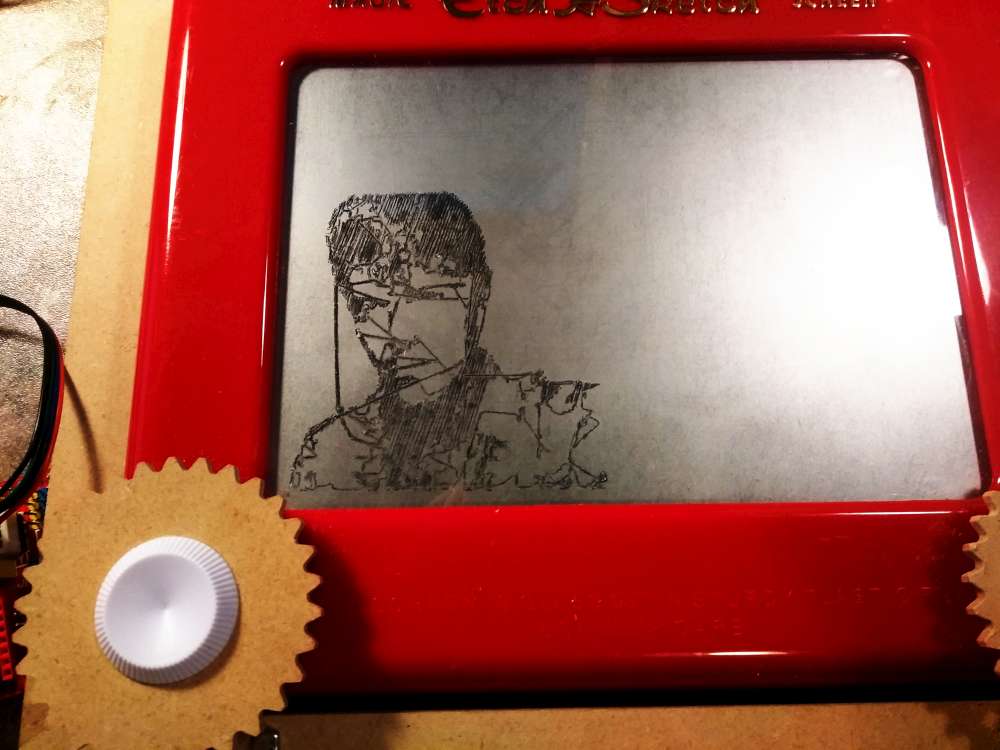

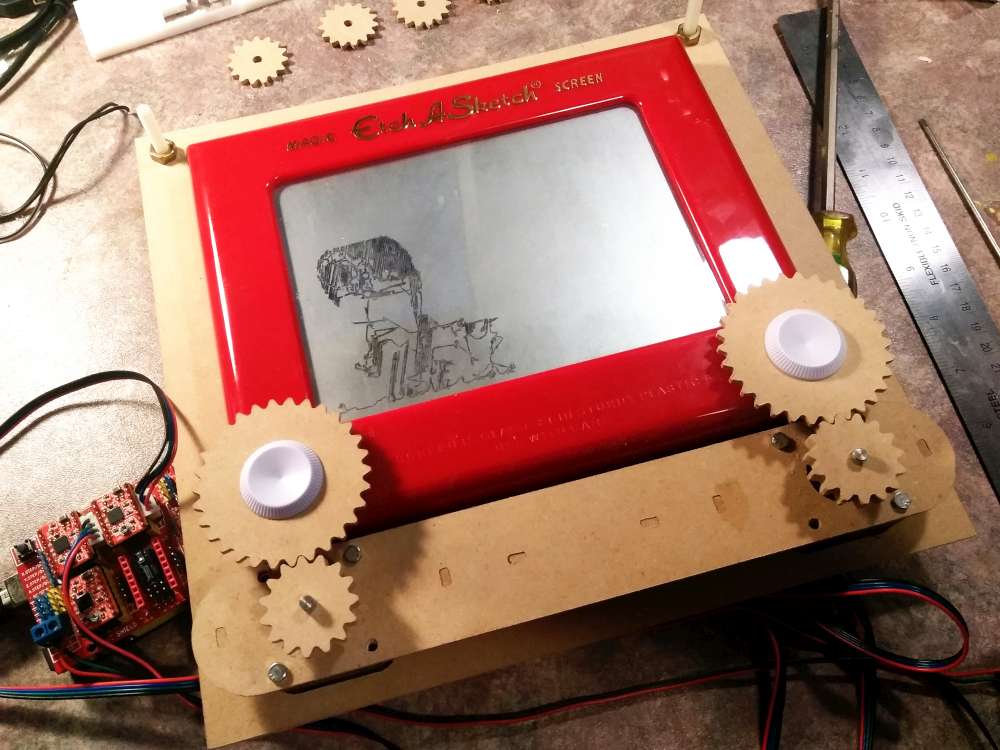

Etch A Sketch

We’ve got a challenge to build a simple CNC system over at hack613.

Here’s my first installment!

How it’s Made

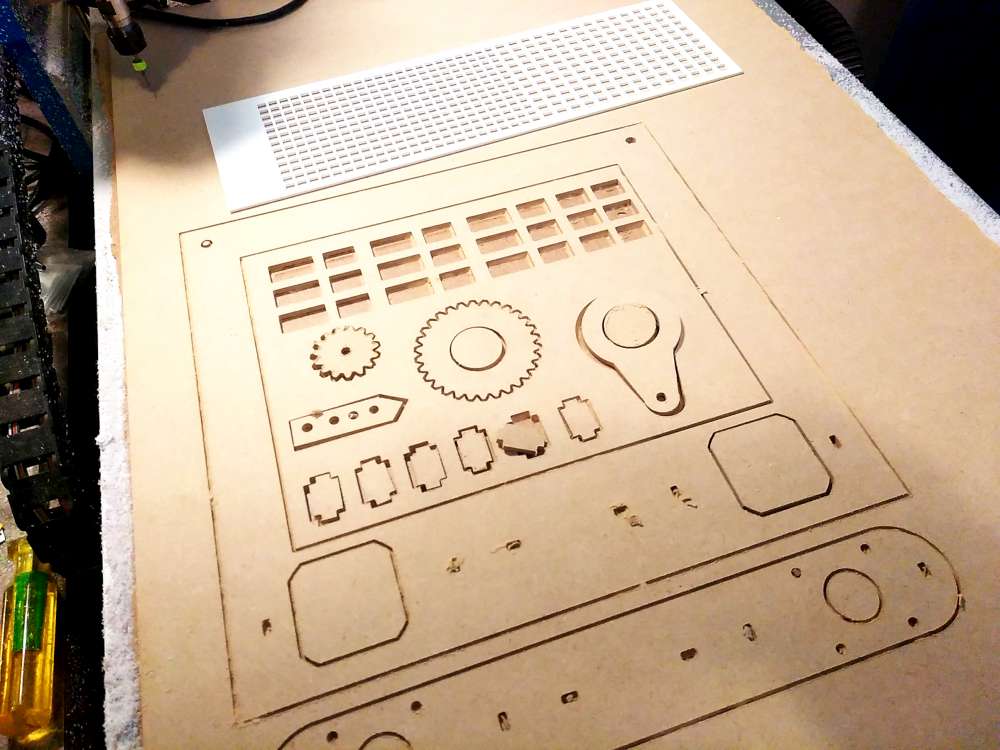

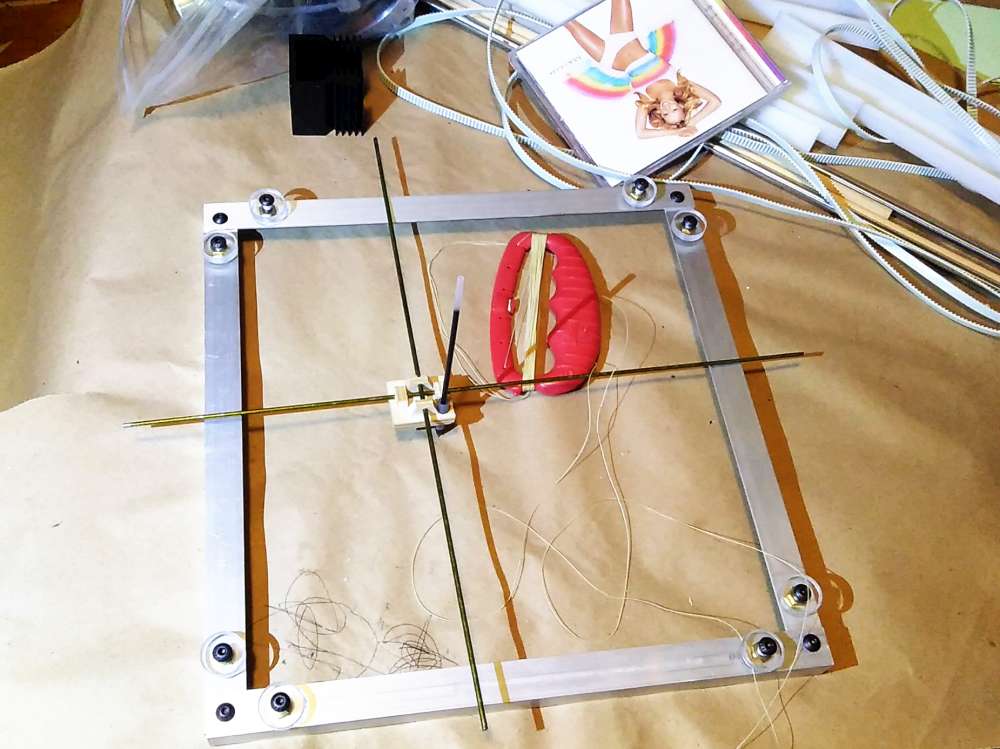

I took some measurements of an Etch A Sketch and drew up a frame to hold it using Sketchup. Download. This can be cut out on a CNC or Laser cutter. I used a CNC.

I attached two Nema 17 stepper motors (using M3 bolts) and wired it up to an Arduino and CNC Shield and stepper drivers. I used a 12V, 2A supply (that might be a little light we’ll see how it does). I turned the current settings on the drivers to half and set the microstepping using jumpers and this chart.

Bill of Materials:

- CNC Shield. A search in ebay for “cnc shield” should reveal lots of these kits with an Arduino, the shield and stepper drivers.

- Two Nema 17 stepper motors. I used these ones.

- 12V Power supply.

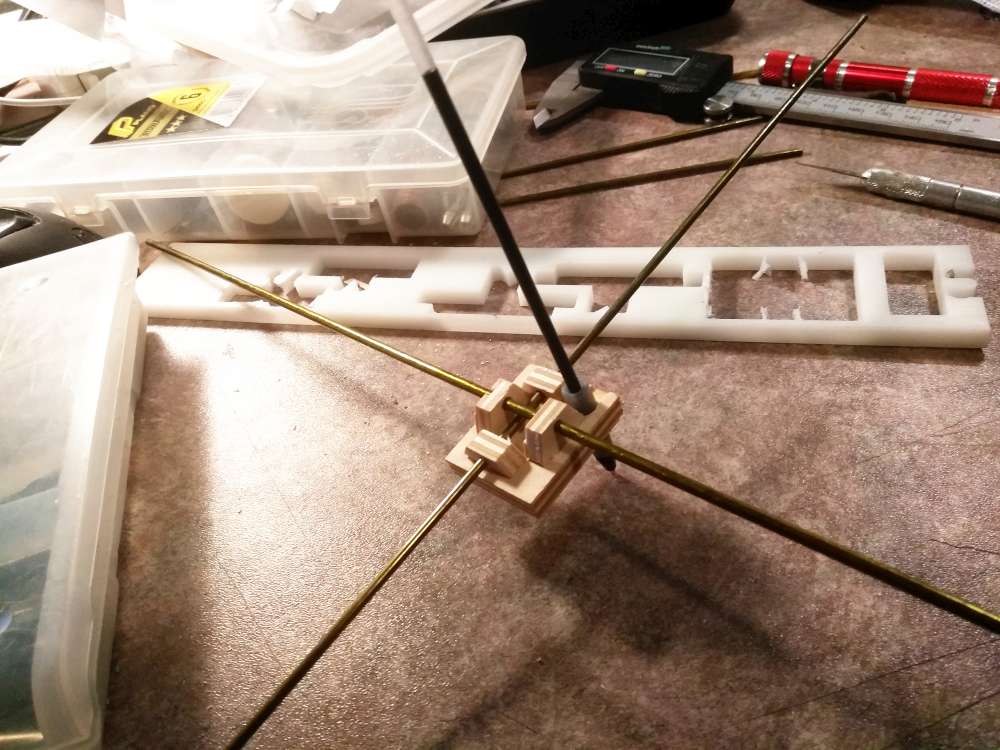

These CNC shields run really well with GRBL. You can load that into the arduino. You then load GRBL controller software onto your computer. I’m using Candle which seems fine. GRBL is easy to set up, you type commands into a command line in your controller software to set up calibration, feeds, speeds and direction. I needed to reverse both X and Y motors ($3=3). The gears I made using Mathias’ Gear Generator Program are 2:1 ratio. With the 1.8 degree motors and that ratio the Etch A Sketch seems calibrated with $100=11.000, $101=11.00 and $102=11.00.

A good starting point for the speed and acceleration:

$110=400.000 (x max rate, mm/min)

$111=400.000 (y max rate, mm/min)

$112=400.000 (z max rate, mm/min)

$120=100.000 (x accel, mm/sec^2)

$121=100.000 (y accel, mm/sec^2)

$122=100.000 (z accel, mm/sec^2)

Related

A nice build.