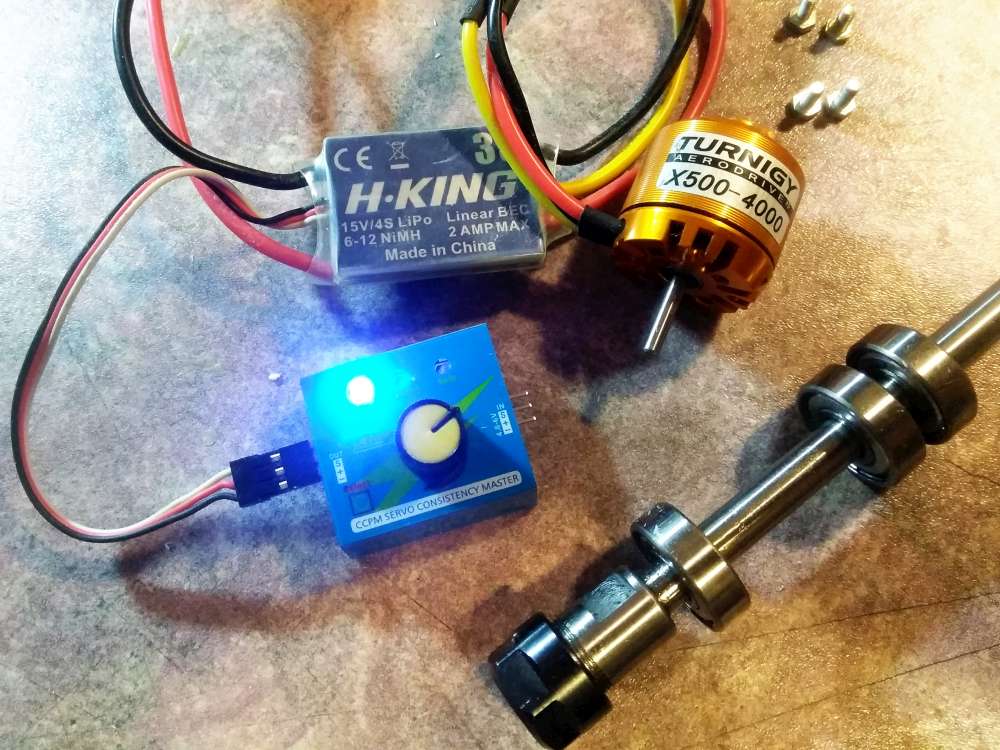

Outrunner Spindle

I’d like to make a small-lightweight spindle for a tiny CNC.

Here’s a candidate. The Turnigy X500-4000.

I think mounting the motor and my ER11 shaft will be easy, the question is how to couple the 5/16″ ER11 to the 3.175mm shaft? I measured the ER11 to be .3125″ or 7.95mm. I’m thinking a pulley or gear system with about 3:1 ratio? I think this is a helicopter motor, perhaps some helicopter parts might be worth considering. I guess it’s a 450 sized helicopter motor so there will be gears available.

Turnigy E500

Turns: 6, Kv: 4000rpm/V

Power: 200W

Resistance: 43mh, Idle Current: 1.9A, ESC Required: 20A+

Especially designed for 3-4Cell lipoly. This motor is made for 450 size helis. Making it an excellent upgrade for the Aling T-rex and other similar helis.

Diameter: 28.4mm

Length: 31.6

Shaft: 3.175mm

Weight: 57g

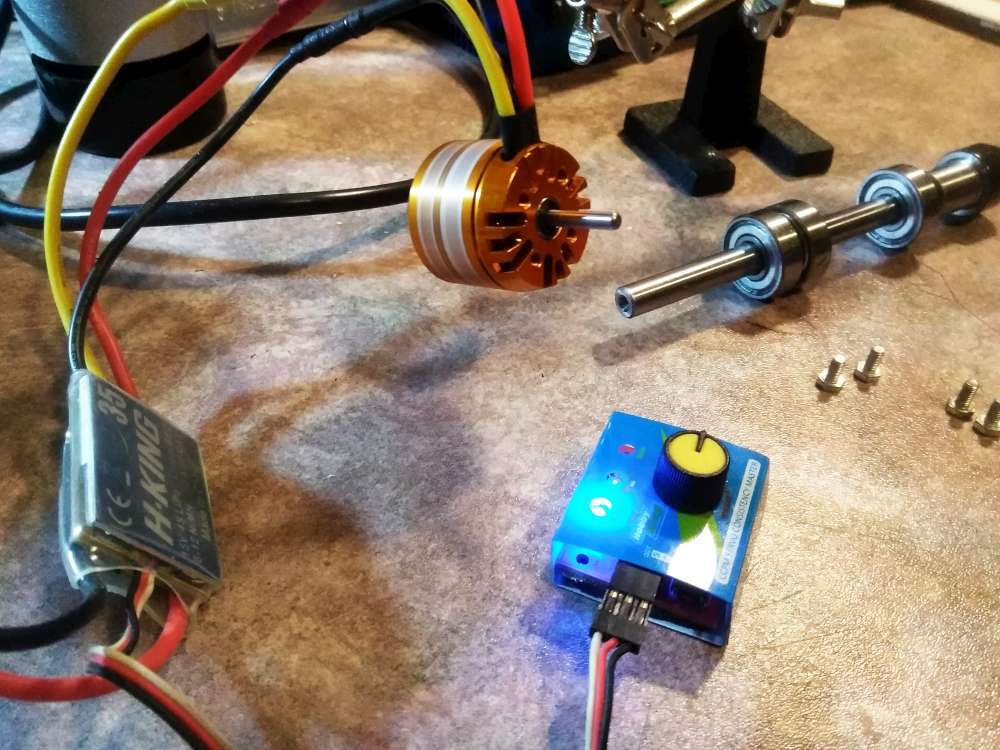

Here it is on the full voltage.

Candidates:

Our shop: https://www.bantamtools.com/collections/spare-parts/products/othermill-pulley-belts

McMaster: https://www.mcmaster.com/94115K119

Gear1 5000 rpm at 12v

Prior art:

http://www.mycncuk.com/threads/3793-Diy-Brushless-Spindle

https://www.kickstarter.com/projects/1029697729/evo-one-desktop-cnc-mill-made-for-anyone?ref=discovery&term=cnc%20mill

https://www.kickstarter.com/projects/otherfab/the-othermill-custom-circuits-at-your-fingertips?ref=discovery&term=cnc%20mill

http://www.dieselrc.com/projects/cncspindle/