In Love With Foam

For me the One-Nite DIY Foam Cutter was just the right machine to fall in love with foam.

For me the One-Nite DIY Foam Cutter was just the right machine to fall in love with foam.

It was perfect for prototyping and experiment. It was multi-purpose with shaping and slicing capability. It was light, portable and easy to use so I had a lot of fun with it.

I got fairly busy cutting foam so the time came for something more specific to my projects and more efficient.

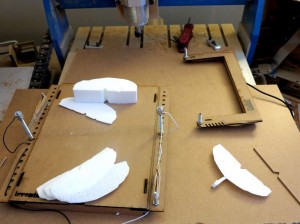

Check out this glider I’m making lately.

I made a separate shaper and slicer.

The shaper is a bow cutter for use with templates and general cutting.

The slicer is highly specialized for cutting many layers at once.

Again I used hardboard for all construction to keep the tooling and bill of materials under control.

One huge improvement was the use of rubber bands at both ends of the cutting wire (rather than just one). To attach the wire to the elastic you simply loop it on the elastic and spin the elastic between your fingers. This twists the wire very finely. Once you have an elastic at each end you loop it over a pair of bolts then anchor the elastics. Apply power to the bolts by trapping the power wires between nuts.

As you can see in the video below the system works like a champ.

Here is is at the Ottawa Mini Makerfaire.

- Photo from JC Batista

Hot Wire Bow Cutter

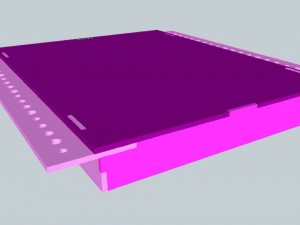

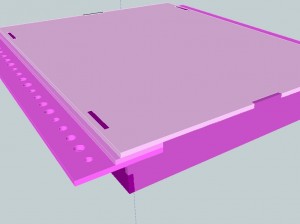

This is a 10′ cutting bow. It accepts a pair of 1/4-20 bolts so you can wrap the cutting wire around it with an elastic. To increase cutting speed I went from the 9V of the One-Nite Cutter to 18V by using a laptop power supply. It’s important to measure the current to make sure whatever power supply you use as enough current.

The was a little tricky to attach the elastics to the features I made so next version will be a little different.

Here’s the sketchup file: HotWireBow

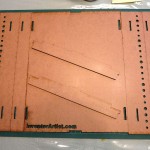

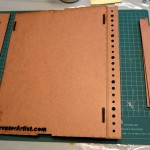

Hot Wire Foam Slicer

If that’s not enough excitement for you here’s a design for just slicing. Bolts point up from those holes and you can span them with nickle chromium wires. The cutters run along the surface. Use the bolt threads to help align the wires so you can “multi-slice” the foam.

I made three hold sizes so different bolts can be tried (1/4″, #8, #10 and #12).

Here I’m also using a laptop power supply. I had to go through my pile to find one that could take 5 amps since this thing draws a lot of power.

That is slick! Cheap toys for the kids to play with and a new toy for the workshop. That’s kewl good job!