DIY Electric Motor for Kids

My friend Bill Kuhl has been making electric motors from kits (among other things of interest to science teachers). The photo with the red wire is one of the kits he made recently. It didn’t look like a satisfying design and it broke my heart to think of kids trying to get that up and running.

My friend Bill Kuhl has been making electric motors from kits (among other things of interest to science teachers). The photo with the red wire is one of the kits he made recently. It didn’t look like a satisfying design and it broke my heart to think of kids trying to get that up and running.

I used to make little motors all the time when I was a kid really loved it. I remember one series of motors that worked particularly well. I used to use a cork or s spool as the armature. Those items seemed to have the right proportions go get the coils the right shape and distance from the axis of rotation. They used to run really fast and shake and wobble like crazy because you could never get the shaft perfectly into the cork/spool.

It was such a satisfying experience so I decided to make an easy electric motor design to see if I can get something together that other people enjoy as I did.

Commutator

I’ve got two ideas in the pipe.

Wound Commutator: I don’t believe this has ever been done. The idea is that the contact area of the commutator will consist of some windings. After they are in place the enamel can be sanded for contact. I think this is the best idea since when winding the armature you wind a commutator pad, then continue with the same wire to wind the whole armature then wind another commutator pad. So it will have a nice flow.

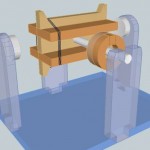

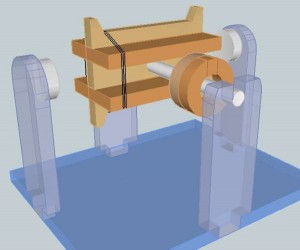

Pop Can Slice: A slice of this metal can be made with scissors and wound into the slots. This type of commutator is what is shown in the diagram below.

Armature

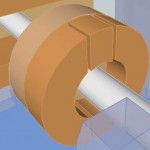

The armature is interlocking wood. You snap the pieces together and start winding. I put a lip at the edge so the wire will not fall off. The windings (shown as black lines) are an inch diameter.

Shaft

I decided to go with open blocks to support the shaft so the whole armature assembly can easily be lifted off. I will experiment with threaded rod or bolts but later I will probably just use a nail. The commutator and armature are currently shown as two separate pieces on the shaft but the plan is to make it all one assembly. So it can turn on the shaft even if the shaft doesn’t turn. I may add a pulley to the rotating assembly so kids can drive something with the motor. Perhaps a little propeller or something.

I’ll cut one out and see if I got the sizing right. I’m a little concerned that the commutator is a little small.