CNC Laser

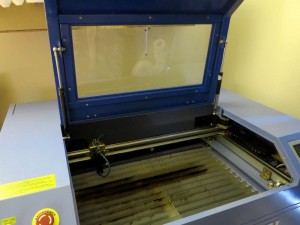

This is my CNC laser cutter.

This is my CNC laser cutter.

Here’s the machine in action.

Chiller Radiator

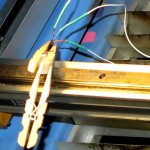

The chiller radiator has had a leak. The radiator consists of aluminum tubing (.375″ 9.6mm outside diameter). There are 16 coils on each side. The straight segments are 8″ and the segments are 2 1/8″ apart. That must be around 50″ of tubing.

Apparently I could have been using antifreeze rather than distilled water as coolant and that would have avoided corrosion of the aluminum. So with the new aluminum radiator I’ll use antifreeze.

I cut the aluminum tubing at the leaky spot and joined it together with rubber tubing and clamps. That works like a champ. I figured the radiator is connected with rubber hose and clamps so clearly that’s not adding any risk. The difficulty is another leak sprung up (perhaps because I disturbed the coil). So the coils must be toast.

Replacing the tubing would be hellish since there’s quite a bit of it and I’d need to do another project on how to bend it. This Home Depot tubing would come to about $60 and then there’s the tools and time for bending it.

Here are the ideas I considered to fix the issue.

- Automotive transmission coolers.

- Universal transmission coolers seem to be around 12 3/4″.

- Motorcycle radiators (they never state sizes so hard to buy).

- Automotive heater core (they never state sizes so hard to buy).

- Computer cpu radiators. They seem to be in multiples of 120mm (4 3/4″). Here’s one on the cheap.

- Air conditioner core.

For a short haul I removed the radiator and shorted the hose. This should be fine for short runs. I’m able to make distilled water using a pot, glass lid and bowl. You float the bowl in boiling water and put the lid upside down to collect the water into the bowl. I added ice to keep it rolling.

Distilled water should be fine with the shorted radiator since there is now just the glass laser tube, plastic hoses and plastic reservoir.

So when I add a radiator I’ll need to look at adding some antifreeze or something. Question is exactly what and how much should I add to the water? Do I need to change the plastic host to accommodate this?

Mirror Alignment

I’ve been wanting to do a full realignment on my laser. I’ve been putting it off since it works pretty well but I had a little fire that caused a bit of damage so now it’s time to do a full overhaul.

Camera and Lighting

Camera and Lighting

My laser came with a camera to install inside for easy monitoring. I want to install that. Also there is an internal light that’s 240V so it doesn’t work. I want to get a 120V lamp to install inside.

Looking Glass

Looking Glass

The looking glass is pretty rough so I’ll make another. I’ts 11.5 x 23″.

Fire

Had a fire which burned up a drag chain, wire, a hose and some other odds and ends. This is fixed. No optical, belt or bearing damage (phew).

It melted the looking glass (mentioned above).

After the fire, nothing worked.. but that’s all fixed.

As far as I can figure the fire was caused by user error. Just wrong settings. And my fixture was flammable. There’s a lesson for me. The work-piece wasn’t big enough to cause damage by burning. But my fixture was.

Related

http://www.metalgeek.com/archives/2005/05/01/000047.php

Kenny’s U Pull (ottawa) bently.

’77 Pontiac Bonneville heater cores are pretty popular for watercooling PCs and they’re very cheap to buy. Have a look here- http://www.overclockers.com/forums/showthread.php?t=304440

wohoo, thanks so much! I’ll have a look at that!

Hey Honus, do you know the dimenions of that heater core?

It measures 6 3/8″ wide x 11″ overall length x 2″ thickness. There’s a pic of it here- http://multi-bot.blogspot.com/2011/01/got-radiator.html

Sorry for the late reply!

Thanks! I’ll see if that fits in my enclosure. In the mean time I have shorted the radiator and am just using the waters heat capacity. Should be okay for short runs.

Try dominion rad on Gladstone. They might have an old cheap rad they can sell you (rebuilt or not). Wrecking yards for car rads, motorcycle wrecking yards for motorcycle rads.

Hi Dan, good idea but I really want to make sure this thing doesn’t leak. Leaking water can do a lot of damage.

Sounds like a job for Sugru!