Rubber Stamp Business Cards

I love my regular laser cut buisness card (and other business cards) but I want an easier way that doesn’t depend on laser.

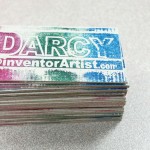

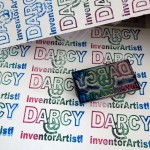

Once you have ink stamps you can make cards out of almost anything so is a great way of upcycling material.

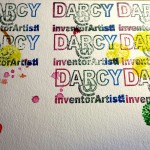

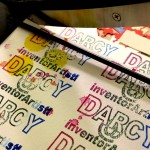

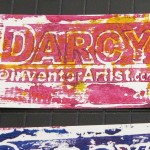

Putting the imprints in a matrix of the work-piece sure makes cutting faster.

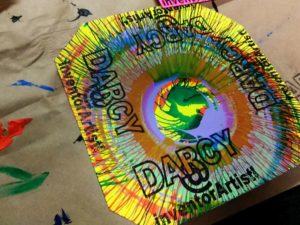

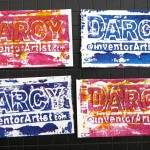

Here are a few I made from some Spin Art experiments.

I also turn cutoffs from card making and other waste to make cards. Also experiments watercolor paper, acrylic ink, fountain pen ink and acrylic paint.

I used cut-offs from my drawing robot projects which gave them a lot of character.

How to Make a Rubber Stamp

Here’s the method I used (off top of my head will refine later).

- Design your stamp using Inkscape.

- Make sure the inking part of your stamp is black and the rest is white or no-fill. It’s important that the black is 100 percent opaque.

- Reflect your stamp on the horizontal axis! Otherwise it will be a mirror image!

- Create a “fence” around your stamp. Draw a container object around your stamp. It can be any closed shape. Make sure the thickness of the line is 1/1000″. The machine will remove all the material within the fence except of course your stamp.

- Make the document size match the size of the stamp.

- Make sure the stamp is centered within the document page frame.

- Save-As-Copy to a PDF. Save the dimensions of the file into the file name.

- Send the PDF to the machine as follows:

- Set the precision to 500 or 1000. Make sure “center” is unchecked. Enter the document size. Select combined vector and raster. Set the vector to 100% power, 75% speed, 500Hz. Set raster power to 100% speed, 60% power. Go to advanced, select stamp. Set the shoulder to 25 and widening to 0. Make sure mirror and fence are unchecked.

- Run that job. It will break the stamp surface.

- Change the raster power to 7-20% depending on the depth you want (7 the deepest). Run the job again.

- Remove your stamp.

- It will be either cut out or nearly cut out. Finish it with a sharp knife.

- Double sided tape it to a block. Add handle to block.

- Stamp!

Related

Published on: Feb 19, 2014 @ 16:00

http://www.youtube.com/watch?v=qURAzAF610o

I’m gonna keep my eyes peeled for any cylinder that I think I can laser…

Wow, that’s a really great idea!

Thanks!

How about rotary lasering the paper traction wheel from a printer, then putting it back in the printer, for a powered rotary stamper!?

Just the roller idea alone might work too. Two rollers could print both sides too.