Custom Vinyl Clocks Ottawa

- Jimmy Hendrix Record Clock More vinyl clocks.

- Bicycle Record Clock

- Ladyface Clock

These LP records were up for disposal so they’re receiving a new life as clocks (store).

These LP records were up for disposal so they’re receiving a new life as clocks (store).

The project has been interesting. I come across items that are nostalgic for myself but I also discover music and history when I make clocks for others. I love that each clock has a story since the records are often old. I feel like an urban archaeologist.

The cutting process is described below but can also be seen on other projects (business cards out of LP records, coasters from records, cutting CD/DVDs).

There are lots of leftover bits of vinyl. I’m making pendants and business cards from them. I also make a lot of other parts from records such as templates for valentine and Christmas cards.

https://www.instagram.com/p/Bro6R1plvrO/?utm_source=ig_web_button_share_sheet

- Vinyl Sugar Skull Clock

- Vinyl Number Clock

- Atomic Clock with Real Electrons!

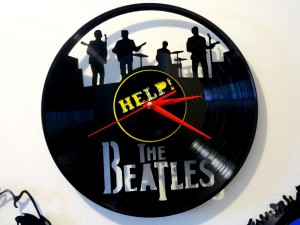

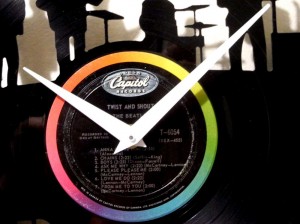

- Beatles Record Clock

- Led Zeppelin Record Clock

- The Doors Vinyl Clock

- Pink Floyd Record Clock

- Metalica Clock

- Bob Dylan Record Clock

- Atomic Rooster Record Clocks

- Everybody Loves Batman

- Banksy Clock

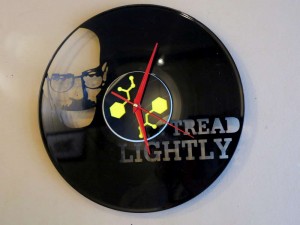

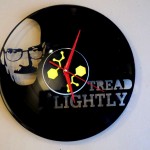

- Breaking Bad Clock

- Lady Clock

- Lady Clock Installed

- Bat Man Record Clock

- Motorcycle Record Clock

- Dylan Clock

- Beatles Clock

- Beatles Clock Cutout

- Paisley Record Clock

- Butterfly Clock

- Led Zeppelin Clock

- Marilyn Monroe Record Clock

- Pink Floyd Cutout Record Clock

- Bob Marley Record Clock

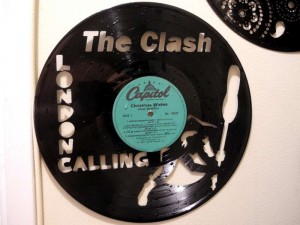

- The Clash Clock

- Johnny Cash Record Clock

- Rolling Stones Record Clock

- Pink Floyd The Wall

- ACDC Record Clock

- Neil Young Record Clock

- Bat Man Record Clock with Cat Woman

- Dance Clock

Hockey

- Sens Clock

Vinyl Clock Portraits

For this I need a few pictures to work from. This takes a bit more time too.

- Portrait Clock

- Portrait Clock

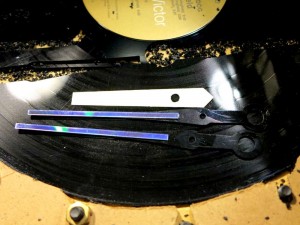

Vinyl and CD Clock Hands

Plain vinyl clock hands are super cool but work better on the lighter colored labels. So I add some CD or DVD material as inlay.

Engraving Vinyl and Micropoetry

I’m able to engrave text onto the label, the groves and the smooth part of a record. This opens a few doors for rationalization, customization and other content.

On light colored labels, label engraving comes out really nice since it exposes the black record.

- Micro-Poetry Clock

Cutting Through the Record Labels

This has come up a couple of times. There’s easy stuff like the Marilyn Monroe clock. It takes a few minutes to clean up the paper since it doesn’t cut exactly the same as the vinyl.

A harder example is this Detroit Red Wings Record Clock. It took numerous tries before cutting all the fine detail without breaking the record. It took over an hour to clean up the label. Also a backing had to be added so the clock movement doesn’t interfere with the design. This is the most difficult and time consuming clock I’ve made to date.

- Marilyn Monroe Record Clock

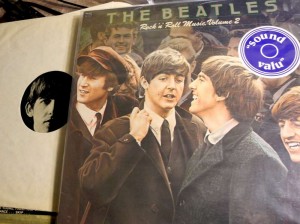

But here’s another angle. Make a hub from another record. In this example we added a layer of colored paper underneath the hub. The cool thing about this angle is your content can cover the entire record. In the Beatles example you see the label through the hub.

- Breaking Bad Clock

Matching Record Theme to Cutout

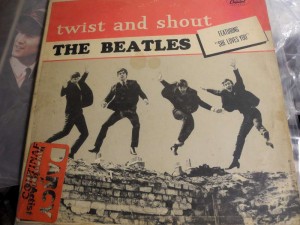

I’m not as thrilled about this unless the records were headed to land fill. I think it’s fun to cut rock and roll albums onto classical records or cut one band into a record of someone who influenced it. Or from the same time period but contrasting music. There’s so much more than just matching your shoes to your purse in life.

I’m not as thrilled about this unless the records were headed to land fill. I think it’s fun to cut rock and roll albums onto classical records or cut one band into a record of someone who influenced it. Or from the same time period but contrasting music. There’s so much more than just matching your shoes to your purse in life.

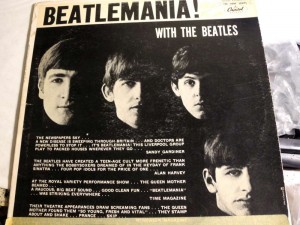

Here’s a job I did to cut out some Beatles records. The records were very high wear so that’s cool.

Interestingly, when I was choosing which side as the front, in one case I chose a side with a 3″ scratch. I knew that scratch told a story for the record owner so I put it in front.

- Beatles Clock Cutout

- Record Clocks

How is Music Recorded?

Clock Mechanisms

How to Cut a Record

One method of cutting a record is using a heated knife (available at any craft store). I’m not sure how safe this is since if you overhead vinyl you get poisonous gasses (polyvinyl chloride releases carcinogens and acid when heated). I’m not sure if a heated knife is hot enough for that.

https://www.youtube.com/watch?v=S09JOT-aKK8

Another method is to use ordinary cutting tools and a rotary cutter such as a dremel mototool. I think if it’s done carefully this can give good results.

The method I’m using is a CNC rotary cutter.

For the design I use Inkscape to trace a path (Path, TraceBitmap, OK). I then cleaned up the trace by simplifying and deleting stuff I didn’t like. I saved the Inkscape file normally and then imported it in Blender. Blender let me export it as a Collada DAE (had to use 3ds for rooster, A for All). Then in Sketchup 2014 I imported it as a DAE. I then saved it as a Sketchup 8 since that’s the one I’m used to. After cleanup in Sketchup to make sure the endmill can pass everywhere, I rendered g-code using SketchUCam and then ran that on the CNC machine.

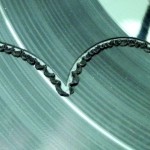

In this case I used a four flute, 1/16? endmill. I ran it at 30 inches per minute cutting speed. I didn’t bring out the techometer to measure the spindle speed but it was pretty low. I bet it was 3500 or 4000 rpm. If I make another of these I’ll check the RPM.

I also tried CNC machine with a two-flute-1/16″ endmill (cutter) at 8670 rpm and 30 inches per minute cutting speed.

I also have a fixture which I made specifically for cutting records. So the record is clamped from the center and edges.

Related

Ottawa Record Stores: The Record Center, The Turning Point (Cooper), Legend Records, Vertigo Records (Rideau),

How to clean a record:

Shape bender plugin.

You can buy them with shipping. If you don’t see the clock you want in the list let me know.

Who buys vinyl records?

Proof of concept published on: Dec 23, 2013 @ 14:48

Hi I’ve been buying old records to try on my CNC router and wondered how the oldest records would cut? They seem to chip easy like bakelite plastics not like the newer vinyl records. I thought someone would know from trial & error?

I’ve not cut any of those yet. Let me know if you find a solution.

Hi, I am just wondering when you started this work! How long have you been working? over 10 years?

This project is pretty new. This will be my 2nd Christmas making the clocks..

This is awesome, just curious though, there is a set of pictures just above the video for “Clock from LP record”, and the picture on the left shows an album with some white cleaner or something on it on the edge, and it looks like another album kind of laying or leaning up above it, can anyone explain to me what im seeing the other album for and what that whitish material is?

It’s ice. The record was in the freezer.

Im intrested in trying this. Did you ever pen down your exact feed and speed settings?

Nice designs.

Vinyl varies quite widely…

Hi,

Thanks so much for sharing this. I’m currently looking for a CNC machine as I run a record ( http://www.rhubarbrecords.com ) store and have lots of spare vinyl with scratches etc. I was wondering if you could point me in the right direction for a good machine please? Something compact and not too pricey.

Cheers

Dylan

Hi,

I’m way over here in Canada…

I think anything that has a cutting area that’s bigger than a record should be fine…

Perhaps seek out your local hackspace and see if they have one to try?

Thanks Darcy,

I will definitely be doing some research before buying a CNC machine. They aren’t cheap!

shipping http://www.shipgreyhound.ca/c/SitePages/GCXStep2.aspx

There probably exists a generation of people that would see the LP as a mystery object. For those of us that have handled vinyl records, this looks marvelous…

Yeah lots of kids probably don’t know about records. Not to mention eight-tracks. But they still make records and there’s a crowd that swears by them…

This is such a great use for old vinyl records that I never want to play again. So for the young kids perhaps you need a CD clock. I know there is redundancy on a CD so how much can you cut away and still recover data. If you cut a burnable CD can you then record on it even if it has a few holes. The censorship possibilities are endless. “CD Redacted by Darcy”.

I was just thinking about that last night. I wonder how well the CDs will cut and if they’re laserable. I was wondering how the data layer would flake off and was thinking if it did it might look interesting…

The other think I was thinking was to try and make the whole clock out of the record with gears and all.

The record after cut idea is super. Oh, by the way, that CNC cutter I’m lending you will cut records no problem…

You just put the dremel on a low setting….

I think it might be possible to have a cooler in the fixture but I’d need to have someone order 1000 records to be cut before I’d figure that one out. 🙂 Might be better to just cool the room. Hmmm. Perhaps just put the machine by the window and open the window…

I saw the pieces you put up at the Atomic Rooster last week – amazing work!

You may be able to integrate peltier coolers into the base to keep your material cooler(although you’d need to use something heat conductive between the cooling plates and the material).

Thanks Chris!

Glad you’re enjoying this stuff.

I thought of that but it’s fairly complicated… I will definitely have to try it if this project keeps at the pace it’s going! In the mean time I’ve managed to increase the efficiency and quality by tweaking other parameters…

I noticed that you keep your records in the freezer? Do they cut better when frozen or did you just think they would taste better? I didn’t see any mention about this. 😉

I believe it cuts better when it’s cold but the problem is it doesn’t stay cold long. Contact with the fixture plus it takes a while to cut it.

At least early in the cut when I’m getting the feed rate set up it’s less sensitive.

I’m finding there are other factors more significant than the temperature… I’ve got a bit of practice making these now…I can make them with one or two passes now that I’m converging on good feed rates and stuff… now that I’m getting fairly good at cutting records the question is what else can I make? They’re such nice material to work with.